+86 187 1857 3593

+86 187 1857 3593

As a car audio manufacturer and supplier,

what process do we follow to fulfill customers' ODM & OEM requirements?

As we know, OEM is designed by car audio distributors themselves. Customers only need to find a car stereo manufacturer and supplier with a better production system to help them complete the production. This process is relatively simple. In the next content, We mainly explain the process of ODM:

1. Car Audio Customers with Project Requirements

At the beginning of cooperation, we as a car radio manufacturer and supplier will receive project information provided by the car radio customer including the main indicators require, customer demand is likely to be a car stereo, car radio, or car DVD player, the project book is the first step for us to reach a consensus on cooperation with our customers. Some of the customers we just mentioned are project managers from car factories and some are wholesale car audio distributors.

2. The Feasibility of the Software

When we receive the customer's project book, not necessarily all of the projects we have the right software solutions available to customers, but in most cases are able to meet customer demand, the current from the MP3 digital media, car DVD player, Apple CarPlay, then Android and Linux system, we have the case of mature experience.

Before starting the formal design process, engineers and customers need to repeatedly communicate and discuss which software solution is more suitable. This is the basic work of ID design, structural design, software, and hardware design, and it also determines product cost performance and product positioning.

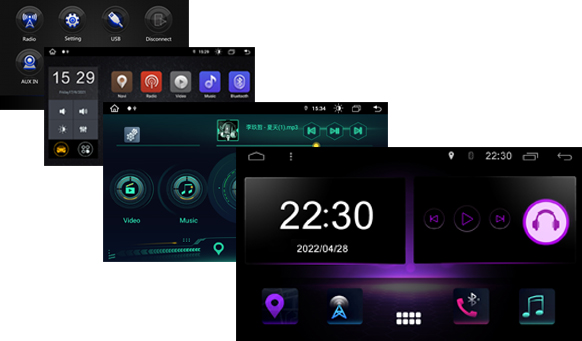

3. The ID and UI Design

When the car stereo and car radio manufacturer' customers confirm the product's software solutions, our ID engineers will be in accordance with customer needs and its own project experience, the appearance of a product design renderings, matching products also need to design exclusive UI interface, confirmed to the customer, in this part of the work, there will be communication and repeatedly modified until the customer to confirm the overall ID and UI design effect.

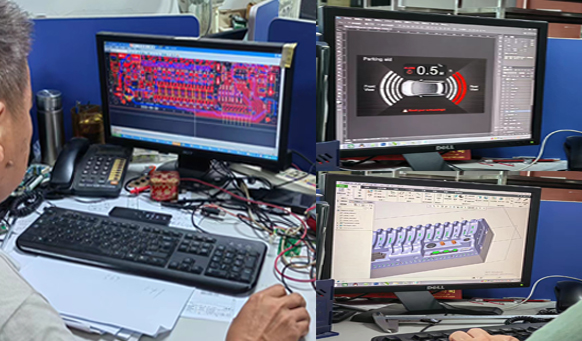

4. Product Structure and Software Design

When the ID finished, structural engineers need to follow 2D drawings to draw 3D charts and then provide information to electronic engineers for PCB design, in addition, structural engineers also need to complete product plastic mold structure, touch screen mold structure, hardware structure mold, and other mold materials needed for production. At the same time, the software engineer needs to start the initial debugging of the software in accordance with the customer's requirements.

5. PCB Electronics Design

After the electronic engineer receives the structural information, he must design the PCB structure according to the clear PCB size and then start to complete the mainboard, TFT board, and core board required by the car stereo. In this process, the electronic engineer needs to work with structural engineers and software engineers together.

6. Provide a Handmade Sample to Customers

After the car stereo manufacturer and supplier has completed all the design work, we will only make a sample of the CNC material for the customer to test and improve. We will not start the formal mold production and mass production until the customer confirms the sample.

Address

Building E, Shangshui Cultural Park, Longgang Dist., Shenzhen, China

CUSTOMER SERVICE

+86 187 1857 3593

REQUEST A QUOTE