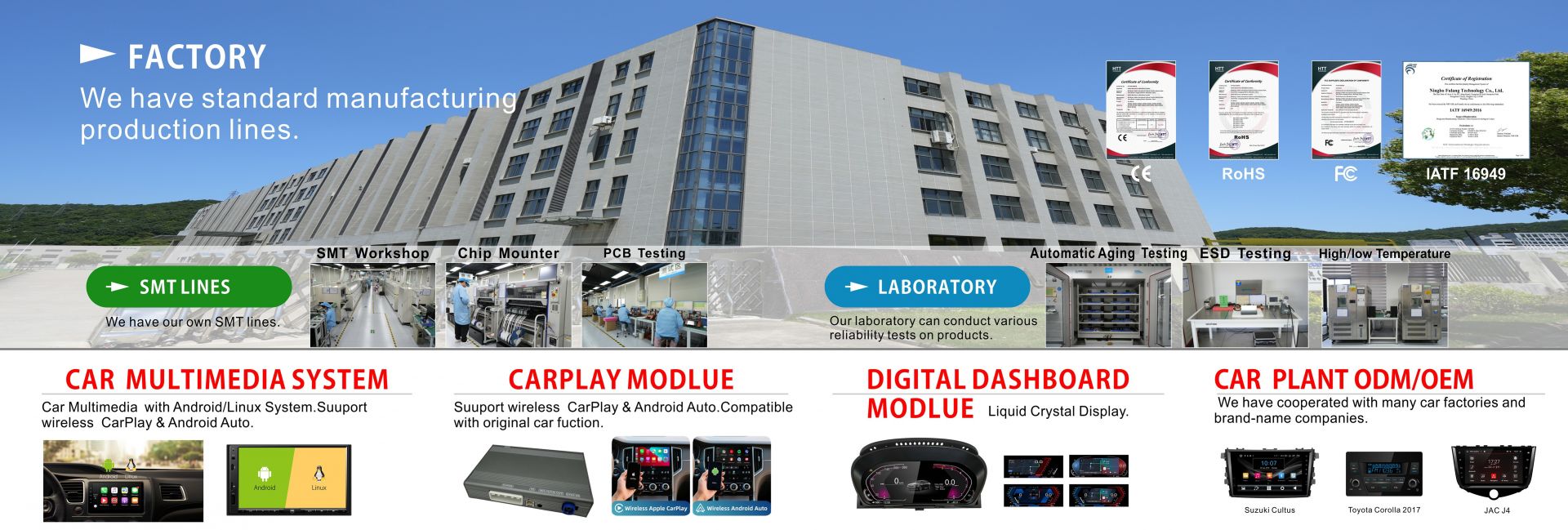

It takes at least three years for a car stereo factory to complete the initial system from the construction of the factory. At this stage, it can essentially only obtain the basic quality certification system of ISO9001. A factory with ISO9001 quality certification can fully meet the production requirements of the aftermarket and semi-before market. Still, to fulfill more difficult car factory project customers, it needs to obtain the internationally recognized IATF16949 production quality system certification. However, IATF16949 certification requires at least 5 years of mature factories, from the scale of personnel, production test equipment, engineering technology precipitation, production process perfection, quality control degree, etc. to meet the IATF16949 factory auditing specifications.

1. Through the meeting presentation of the factory staff, you can have a basic understanding of the development history of the factory, its current scale, the status of production and testing equipment, collaborating customers, representative project cases, and the corporate development visions, etc.

2. Guided by factory staff, you can visit and evaluate the office area, material management department, engineering department, QC department, and laboratory, as well as the current status of the production workshop and warehouse to get a general impression of the factory.

3. Warehouse evaluation. For the IQC department, you can mainly check whether the factory has a strict division of inspection zone, IQC zone & defects zone, and a daily record of IQC inspection reports, testing standards & return records. In addition, whether each core material has engineering-signed samples for IQC control testing. Moreover, check whether the warehouse has clear storage area divisions for different materials, such as a hardware section, a plastic section, a wire section, a PCB section, a valuable materials section, etc. Examine whether the valuable materials section, such as an IC or a display screen, has a consistent temperature and humidity preservation environment. The valuable materials section requires a thermometer, hygrometer, air conditioner, and humidifier.

4. SMT workshop evaluation. When transferring from the PCB section to the SMT workshop, ensure that there is a dedusting and destaticizing area at the entrance of the SMT workshop, and SMT employees and reviewers should wear anti-static clothing and hats correctly. In the SMT workshop, check whether there are SMT reports, AOI inspection reports, and furnace temperature record reports for daily production, the way solder paste is kept, and the location of the refrigerator (unused and unpacked solder paste must be kept in the refrigerator).

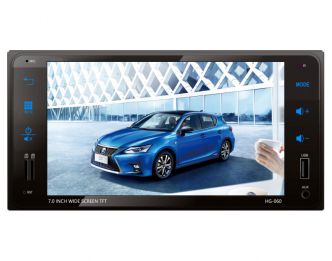

5. PCBA evaluation. After the completion of the SMT assembly of electronic components, the semi-finished PCBA will be sent to the post-welding department of the production line. PCBA welders need to manually weld larger components, such as inductors, to the PCB. You need to check whether the PCBA operators are wearing anti-static bracelets, whether there is a temperature detection standard for the coil head and the detection equipment as well as the cleaning method of tin dross, etc. These are the details of quality control that determine whether there are quality risks in the long-term use of the product.

6. Assembly Evaluation. Evaluate the staff of the assembly department, the production technology instructors, and repair workers, based on the following aspects. First of all, each worker in the operation must wear anti-static bracelets, and each assembly line has an initially finished product inspection QC staff at the end position. The defective assembled finished products QC staff preliminary detects need to have a clear placement area, waiting for repair staff to repair. In addition, you can review the work sessions and daily repair reports of repairers who assemble defective products, and check whether there are clear work instructions for the products to ensure that workers' procedures are uniform and clear.

7. Aging room evaluation. Check whether 100% of the assembled finished products enter the aging room for the aging test, whether there are clear specification documents on the temperature, standard, and time in the aging room, and how the processing process of aging defective products is operated.

8. Finished product QC evaluation. After aging, qualified finished products will be handed over to the QC department for detailed testing, you need to check whether each QC station has clear testing content and standards. Besides, review QC reports, QC defective products handling and process display, and QC station work instructions display.

9. Packing evaluation. After QC strict testing of the finished product, it will be handed over to the packing department to complete the final packaging of the finished product. You can check whether the factory staff has carefully carried out the external visual inspection, wiped the film, verified the product barcode, and confirmed the stickers.

10. Before formally entering the warehouse into the ERP system, the batch orders that are completed and packed need to be randomly inspected by QA to finally confirm the quality of the batch orders. You need to check whether the QA department has clear documentation of the sampling criteria and the sampling methods.

11. After QA testing, when qualified batch products enter the warehouse, you can check whether the factory's PMC department management uses a professional ERP system to avoid manual operations.

English

English Russian

Russian